News

Pyrolysis for plastic recycling

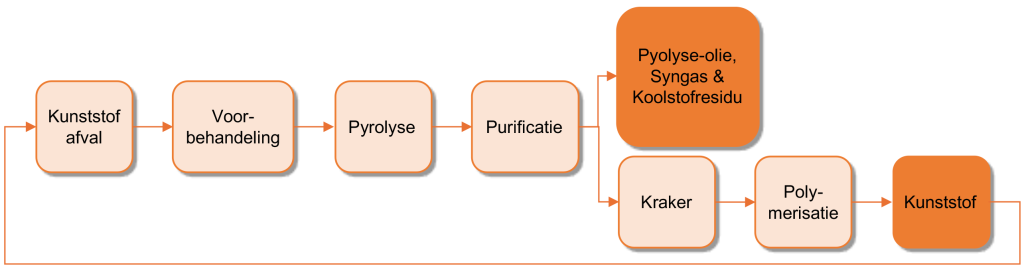

Pyrolysis is a thermochemical process that breaks down residual waste at high temperatures in the absence of oxygen, resulting in the production of valuable products such as pyrolysis oil, synthetic gas (syngas) and carbon residue. This technology is seen as a promising solution for processing difficult-to-recycle plastic waste and plays a crucial role in the material transition to a circular economy.

In recent years, pyrolysis technology has made significant progress, spurred by the growing need to find sustainable solutions for plastic waste. This recycling technology can process plastics that are difficult to recycle, such as mixed, colored and contaminated plastics. It also reduces dependence on fossil oil and enables the production of high-quality polymers, for the food industry, for example.

Simplified pyrolysis recycling process

Startups

Many startups have emerged developing new applications of pyrolysis, but many of them disappeared due to challenges of operational scale, cost control, feedstock supply and off-take agreements. Nonetheless, there are some companies that managed to overcome these challenges and established a strong position in the market:

Plastic Energy: A UK-based chemical recycler, has operating plants in the Netherlands, France and Spain. The recycled oils from these plants are used for virgin-grade food packaging. The Dutch plant processes 20,000 tons of mixed plastic waste. Major chemical companies such as SABIC, TotalEnergies and ExxonMobil partner with Plastic Energy, and their recycled plastics are used in packaging for brands such as Unilever and Tupperware. By 2021, Plastic Energy has raised €145 million to accelerate the global expansion of their recycling technology and plants.

BioBTX: A chemical recycler based in Groningen, has raised €80 million to build their first commercial plant in Delfzijl. This plant will use Integrated Cascading Catalytic Pyrolysis (ICCP) technology to convert 20,000 tons of mixed plastic waste into renewable aromatics annually, replacing fossil raw materials and recycling low-grade plastic waste into high-value chemicals.

Pryme: A Dutch company focused on chemical recycling of plastic via pyrolysis, went public in 2021. It raised €50 million and €30 million in 2022 and 2023, respectively. This year, €10 million was raised from Taranis Carbon Ventures and €5 million from InnovationQuarter to further develop and scale up their pyrolysis technology. It currently processes 40,000 tons of low-grade plastic waste.

Capital and M&A rounds of a number of key pyrolysis recycling specialists in Western Europe

Source: JBR analysis

Major investment challenge

Large petrochemical companies are increasingly investing in pyrolysis technologies as a strategic opportunity to reduce their dependence on fossil fuels and reduce their carbon footprint. By investing in pyrolysis, these companies can diversify their portfolio and respond to the growing demand for sustainable solutions.

For now, there is a major investment challenge ahead to eventually recycle the volumes of increasing plastic (plastic) waste production.

The European Union has established strict rules and guidelines to promote the transition to a circular economy. One important measure is the "admixture obligation," which requires producers to use a certain percentage of recyclate in their products. This percentage, currently 15%, will increase to 30% by 2030. EU regulations also further encourage the development and implementation of recycling technologies by making grants and financial support available for research and development. In addition, the EU is imposing increasingly stringent waste management and recycling requirements, increasing the need for innovative solutions such as pyrolysis.

Pyrolysis technology has the potential to contribute to the materials transition. Despite the challenges faced by many startups, there remain some stable players making significant progress and attracting investment. Petrochemical companies are playing a crucial role by taking risks and investing in these technologies. With the support of EU legislation, pyrolysis seems well positioned to play a key role in the future circular economy.

Transaction overview of major pyrolysis recyclers

Contact the team personally

Would you like to spar with one of our experts? We are ready to talk with you.

Ronald van Rijn

Managing Partner JBR

Rogier Tigchelaar

Senior Consultant Corporate Finance

Frank Steenhuisen

Associate